330903-00-05-70-12-00 Bently Nevada 3300 NSv Probe FluidLoc Cable

Manufacturer:

Bently Nevada

Product No.:

330903-00-05-70-12-00

Condition:

In Stock

Product Type:

3300 NSv Proximity Probe

Product Origin:

USA

Weight:

500g

Shipping port:

Xiamen

Warranty:

12 months

UBEST – Vertrauenswürdiger globaler Lieferant für Automatisierungsteile

Wir bieten eine große Auswahl an vorrätigen Ersatzteilen für die industrielle Automatisierung. Alle Produkte haben eine 12-monatige Garantie und eine 30-tägige Rückerstattung bei Qualitätsproblemen.

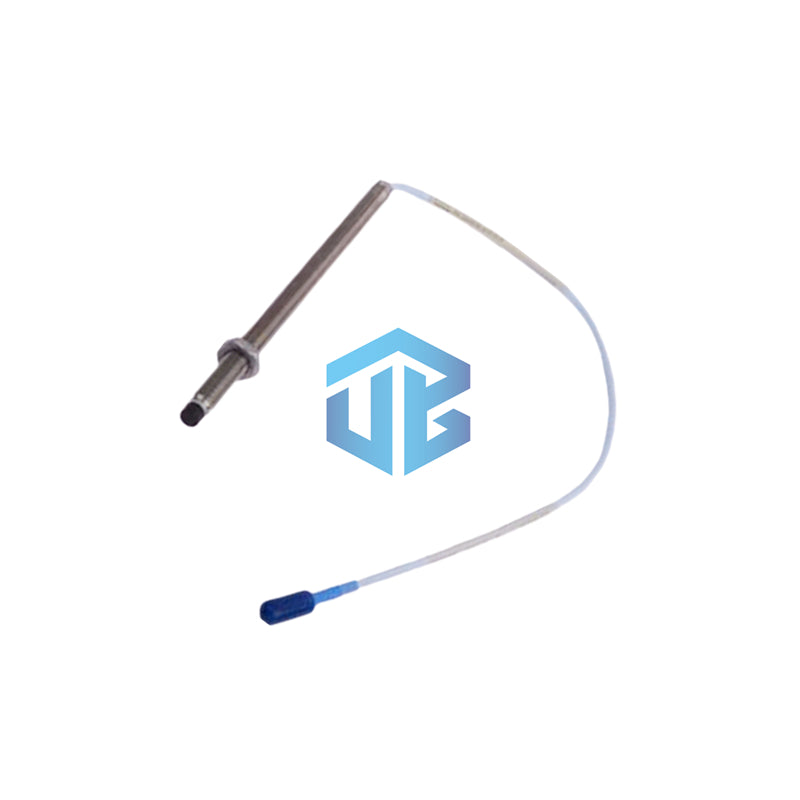

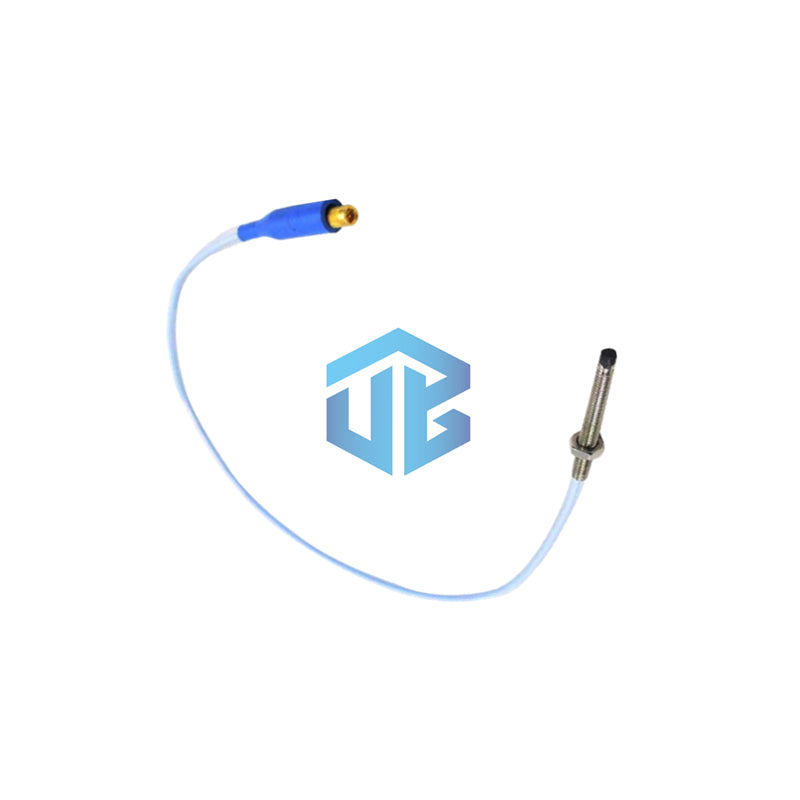

Bently Nevada 3300 NSv Proximity Probe with FluidLoc Cable

Discover the advanced 330903-00-05-70-12-00 industrial vibration probe from Bently Nevada. This new, original sensor features specialized FluidLoc cable technology and comes in factory packaging with full 12-month coverage. We ship globally via FedEx, UPS, and DHL.

Complete Package

- Authentic Bently Nevada 330903-00-05-70-12-00 Probe

- Factory Sealed Packaging with Documentation

- 12-Month Comprehensive Warranty

For complete technical information: Download Full System Datasheet

Model Number Details

The complete model number 330903-00-05-70-12-00 reveals all specifications:

- 330903: Core NSv probe with M8X1 threading

- 00: No unthreaded section

- 05: 50mm extended case length

- 70: 7.0 meter total cable length

- 12: FluidLoc cable with ClickLoc connector

- 00: Standard industrial certifications

Technical Specifications

- Manufacturer: Bently Nevada

- Measurement Range: 1.5 mm (60 mils)

- Optimal Gap: 1.0 mm (40 mils)

- Output Signal: -1 to -13 Vdc

- Sensitivity: 7.87 V/mm (200 mV/mil)

- Electrical Resistance: 5.9 ± 0.9 Ohms

- Temperature Rating: -52°C to +177°C

- Cable Type: FluidLoc 75 Ω coaxial

- Case Material: AISI 304 Stainless Steel

- Tip Material: Polyphenylene Sulfide (PPS)

- Minimum Bend Radius: 25.4 mm (1.0 inch)

- Maximum Torque: 0.56 N•m (5 in•lb)

- Frequency Response: 0 to 10 kHz (±3 dB)

- Sealing Material: Viton O-ring

- Thread Engagement: Maximum 12 mm

Installation Instructions

- Hand-tighten only - no tools required

- Maximum installation torque: 0.56 N•m

- Ensure proper thread engagement (max 12 mm)

- Maintain minimum cable bend radius of 25.4 mm

- Set optimal target distance at 1.0 mm (40 mils)