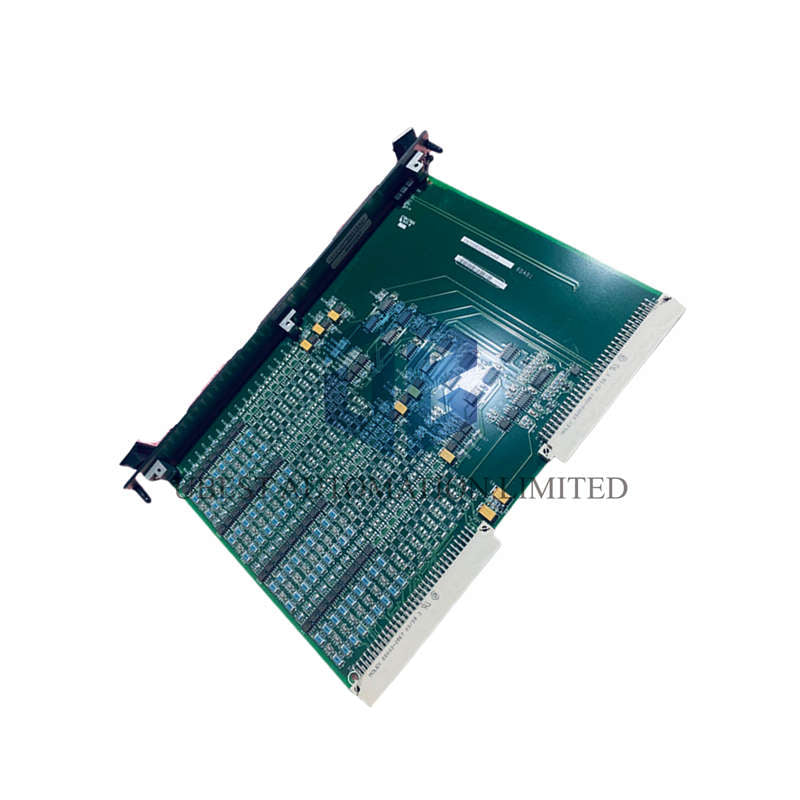

GE IS200ESELH2AAA - EX2100 Exciter Selector Board

Manufacturer:

GE

Product No.:

IS200ESELH2AAA

Condition:

In Stock

Product Type:

Exciter Selector Board

Product Origin:

USA

Weight:

500g

Shipping port:

Xiamen

Warranty:

12 months

UBEST – Trusted Global Automation Parts Supplier

We offer a wide range of in-stock industrial automation spare parts. All products come with a 12-month warranty and a 30-day refund for quality issues.

GE EX2100 Exciter Selector Board IS200ESELH2AAA

The IS200ESELH2AAA serves as a critical control component in power generation systems. This Exciter Selector Board from General Electric ensures precise gate pulse distribution within EX2100 excitation systems. It maintains optimal generator performance through accurate timing control.

Technical Specifications & Features

- Manufacturer: General Electric

- Part Number: IS200ESELH2AAA

- Series: EX2100 Excitation Control System

- Function: Exciter Selector Board (ESEL)

- Operating Temperature: 0°C to 70°C

- Storage Temperature: -40°C to 85°C

- Signal Processing: 6 logic-level gate pulse inputs

- Output Channels: Controls up to 6 gate pulse amplifiers

- Board Coating: Conformal coating for protection

- Power Requirement: 24V DC system power

- Response Time: <5 milliseconds signal processing

- Isolation Voltage: 1500V AC minimum

- Humidity Tolerance: 5% to 95% non-condensing

- Vibration Resistance: 2.5G @ 10-500 Hz

- Shock Rating: 10G, 11 millisecond duration

System Integration & Operation

- The board interfaces directly with the EMIO master I/O board for signal reception.

- It processes six independent gate pulse signals with precise timing synchronization.

- Redundant systems require two boards for M1 and M2 control paths.

- The active board selection depends on signals from the C controller.

- Output signals drive EGPA boards in the power conversion cabinet.

- Three status LEDs provide instant visual feedback for power, activity, and gating.

- Conformal coating protects against moisture, dust, and chemical contaminants.

- The board operates seamlessly within GE's Speedtronic control architecture.

Installation & Maintenance Procedures

- Always de-energize the complete exciter system before beginning work.

- Verify power indicators on EPDM and EPSM supplies show no power.

- Confirm all three status LEDs on the board front panel remain unlit.

- Loosen the captive screws at the top and bottom of the faceplate.

- Raise both ejector tabs simultaneously to unseat the board from its slot.

- Gently pull the board straight out using both hands for even removal.

- Slide the replacement board carefully into the designated slot.

- Press firmly on the faceplate top and bottom to begin seating the board.

- Alternately tighten the faceplate screws to ensure square seating.

- Restore system power and verify proper LED status indication.

Diagnostic Indicators & Monitoring

- Green LED 1 illuminates when board receives proper operating power.

- Green LED 2 activates when the board receives enable signal from Control C.

- Green LED 3 indicates active gating mode with gate inputs from EMIO.

- All LEDs off typically indicates complete loss of board power.

- LED pattern abnormalities suggest control signal or board faults.

- Regular visual inspection of LEDs provides quick health assessment.

- No jumpers or test points simplify maintenance and reduce adjustment errors.

- Board status integrates with overall EX2100 system diagnostics.

Packaging & Shipping Information

- Each board ships in certified anti-static protective packaging.

- Packaging includes cushioning material to prevent transit damage.

- All units undergo pre-shipment testing to ensure functional integrity.

- We ship globally via FedEx, UPS, and DHL express services.

- Most orders process within 24 hours with tracking provided.

- This product includes comprehensive 12-month warranty coverage.

Professional Technical FAQ

- How many ESEL boards does a redundant EX2100 system require?

- Redundant control configurations need two identical ESEL boards for proper operation.

- What do the three status LEDs indicate during normal operation?

- They show power status, controller enable status, and active gating status respectively.

- Can this board operate in high-vibration environments?

- Yes, it withstands vibration up to 2.5G and shock up to 10G for industrial durability.

- What is the purpose of the conformal coating on the PCB?

- This coating protects against moisture, dust, and chemical contamination in harsh plants.

- How does the board interface with other EX2100 components?

- It connects to EMIO for inputs and drives EGPA boards through output cabling.

© 2025 Ubest Automation Limited. All rights reserved.

Original Source: https://www.ubestplc.com/

Contact: sales@ubestplc.com Phone: +86 180 3000 5825