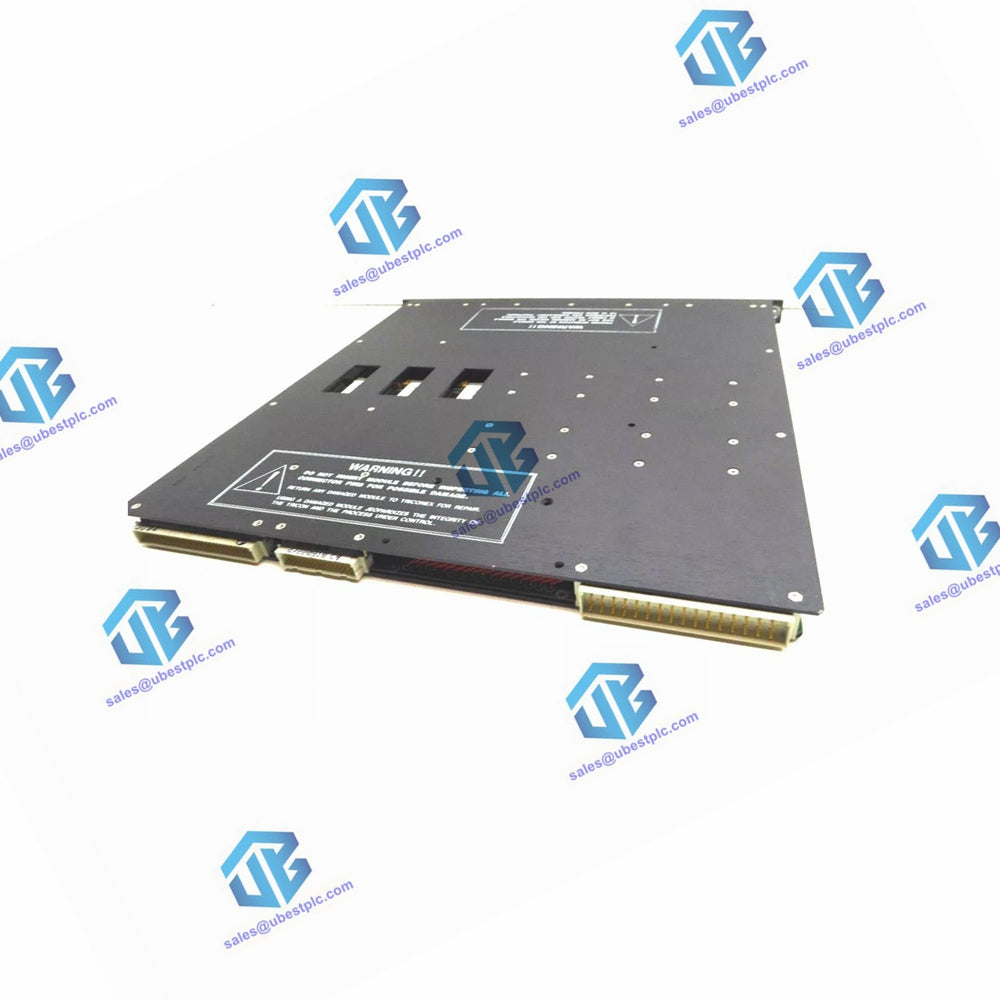

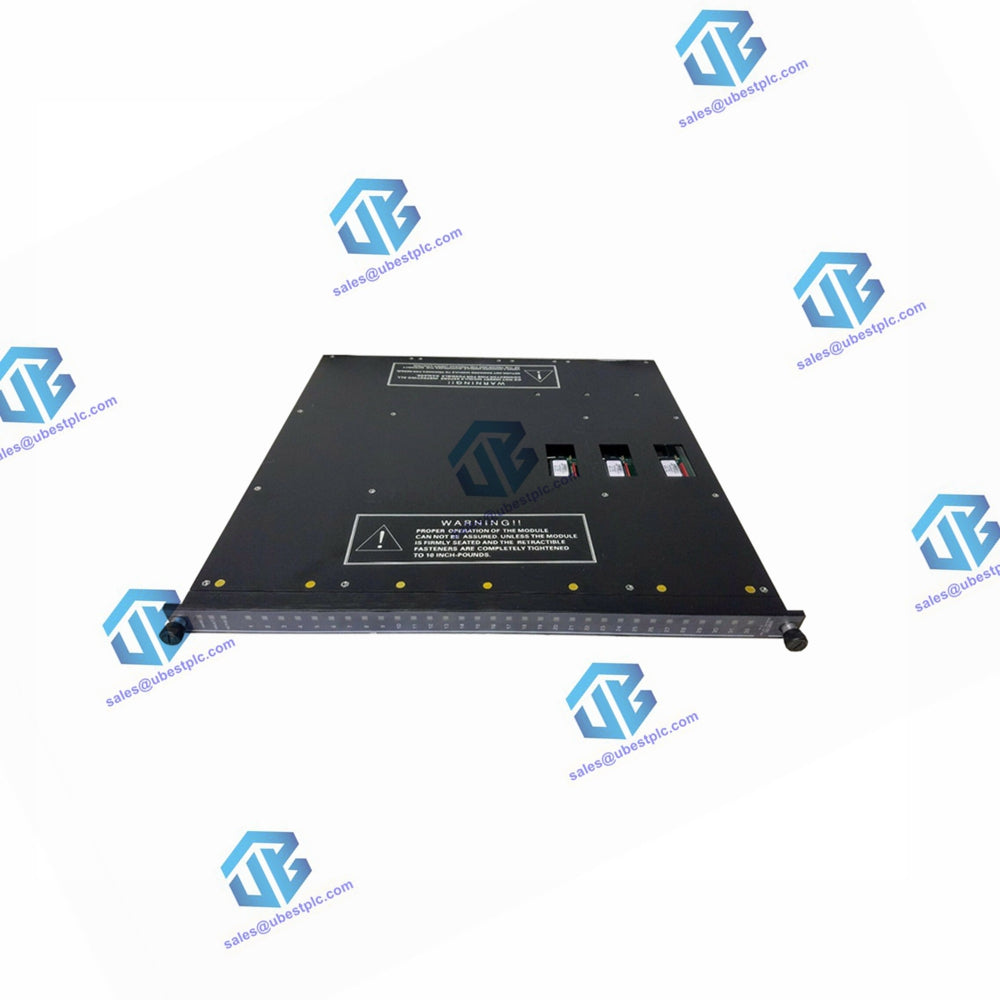

Triconex 4119 Module – 4-Port Serial, Centronics Parallel, Industrial I/O

UBEST – Trusted Global Automation Parts Supplier

We offer a wide range of in-stock industrial automation spare parts. All products come with a 12-month warranty and a 30-day refund for quality issues.

Triconex 4119 Enhanced Intelligent Module

Triconex 4119 serves as an enhanced intelligent module for serial and parallel communications in control systems.

Core Technical Specifications

- The module accepts a 24 VDC nominal supply within an 18–32 VDC input range.

- Typical power consumption measures 5 W during normal operation in control cabinets and racks.

- Four configurable serial ports support RS-232, RS-422, or RS-485 for flexible device connections.

- The serial ports work up to a maximum baud rate of 115,200 bps for fast data links.

- The module includes one isolated Centronics parallel port with a robust 500 VDC isolation rating.

- Support TriStation and Modbus RTU/ASCII protocols for easy integration with Tricon systems and PLCs.

- Operate safely across -20°C to +60°C ambient conditions for typical plant installations.

- Unit dimensions measure 20.3 cm × 12.7 cm × 5.1 cm for compact cabinet mounting.

- The module weighs 4.5 kg and includes factory-applied protective ends for shipping.

Extended Electrical & Performance Data

- Provide per-port termination and bias options to optimize RS-485 network stability and signal clarity.

- The module maintains low latency under full throughput to keep control loops responsive and tight.

- Design offers high common-mode rejection to reduce noise from long serial cable runs in plants.

- Employ robust transient protection on power and I/O to resist industrial surges and switching spikes.

- Use corrosion-resistant contacts and conformal coatings for long life in humid or coastal environments.

Installation Guide

- Mount the module on standard rack rails and keep at least ten centimeters clearance for airflow.

- Route serial and parallel cables away from high-power motor feeds to reduce induced interference risks.

- Terminate RS-485 lines with correct polarity and recommended resistive termination to prevent reflections.

- Use properly sized power wiring and a stable DC source rated within the eighteen to thirty-two volt range.

- Verify TriStation and Modbus settings during commissioning to ensure proper register mapping and timing.

Packing List

- One Triconex 4119 enhanced intelligent module with factory protective caps installed for transport.

- One quick-install guide with pinouts, wiring diagrams, and basic configuration steps for technicians.

- One packing slip showing serial number, firmware revision, and factory inspection tag for traceability.

Product Benefits & Selling Points

- Four configurable serial ports let you connect many field devices using one module footprint.

- High baud support improves throughput for fast telemetry and reduces polling cycle times.

- Isolated Centronics port protects control logic and prevents ground loops across parallel lines.

- Wide operating temperature keeps the module reliable in cold stores and hot plant rooms alike.

- Compact size and standard mounting save cabinet space and simplify retrofit projects in panels.

Shipping & Warranty

- We ship via FedEx, UPS, or DHL with tracking and insured options for global orders.

- The product includes a standard 12-month warranty covering defects in materials and workmanship.

FAQ

-

Q1: What serial modes can the 4119 ports use?

Configure each port as RS-232, RS-422, or RS-485 based on your device and cable plan.

-

Q2: How do I achieve the best RS-485 reliability over long runs?

Apply termination resistors, keep cable twists intact, and preserve proper ground references.

-

Q3: What steps confirm Centronics port isolation during testing?

Perform an isolation measurement between parallel port and chassis to verify the 500 VDC rating.

-

Q4: How should I prepare for firmware or protocol updates in TriStation environments?

Back up configuration, schedule maintenance windows, and validate updates in a test rack first.

-

Q5: What environmental checks prevent early failure in harsh installations?

Monitor ambient temperature, check seals, and avoid corrosive exposure near the module location.